Technology

Creping and Surface Processing

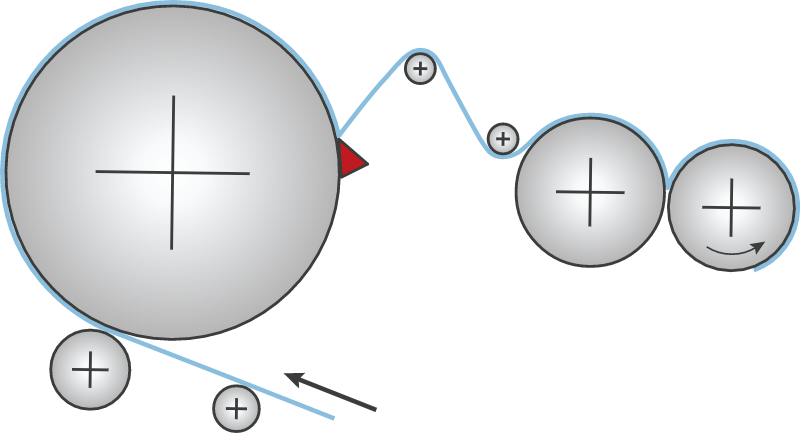

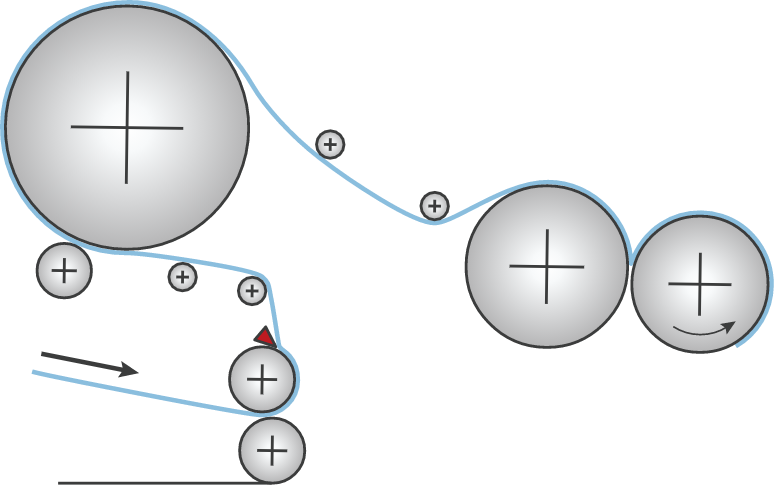

Creping

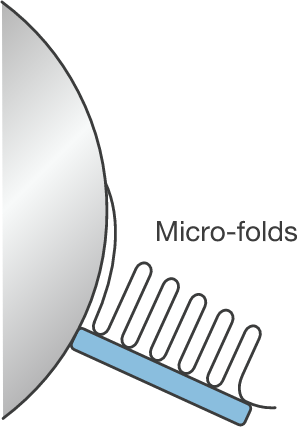

In the creping process, paper is placed on a roll or dryer cylinder and then scraped off with a doctor blade to create crepe-like wrinkles. This three-dimensional alteration of the paper’s layered structure enhances its elongation when stretched in the running direction of the machine. Additionally, it increases the paper surface area, improving its water absorption and breathability.

Dry Creping

Wet Creping

Creping Overview

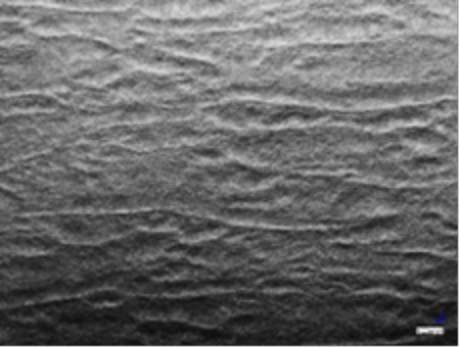

Creped Surface

Surface of General-Purpose

Printing and Writing Paper

The following are key products crafted

with these technologies:

- Liquid Filtration Paper

- Tissue Paper

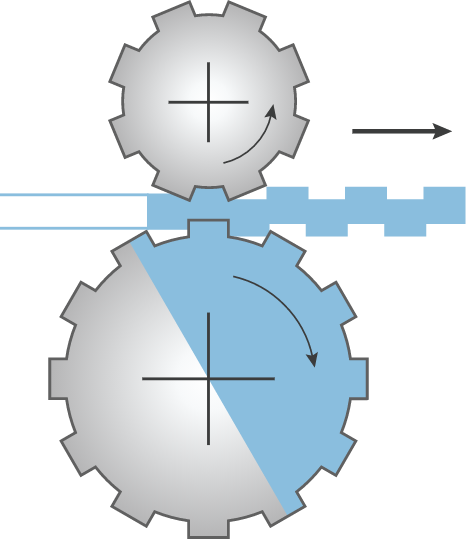

Embossing

Embossing involves using a machine that combines an engraved embossing roll with a paper roll made of softer material. The pattern of the embossing roll is transferred to the paper roll, creating a pattern of both concave and convex elements. As the paper passes between the embossing roll and the paper roll, high pressure is applied to imprint the roll pattern onto the paper, resulting in a design with clear and deep patterns.

Embossing on Both Sides

Embossed Surface

The following are key products crafted

with these technologies:

- Grained Paper

- Textured Paper

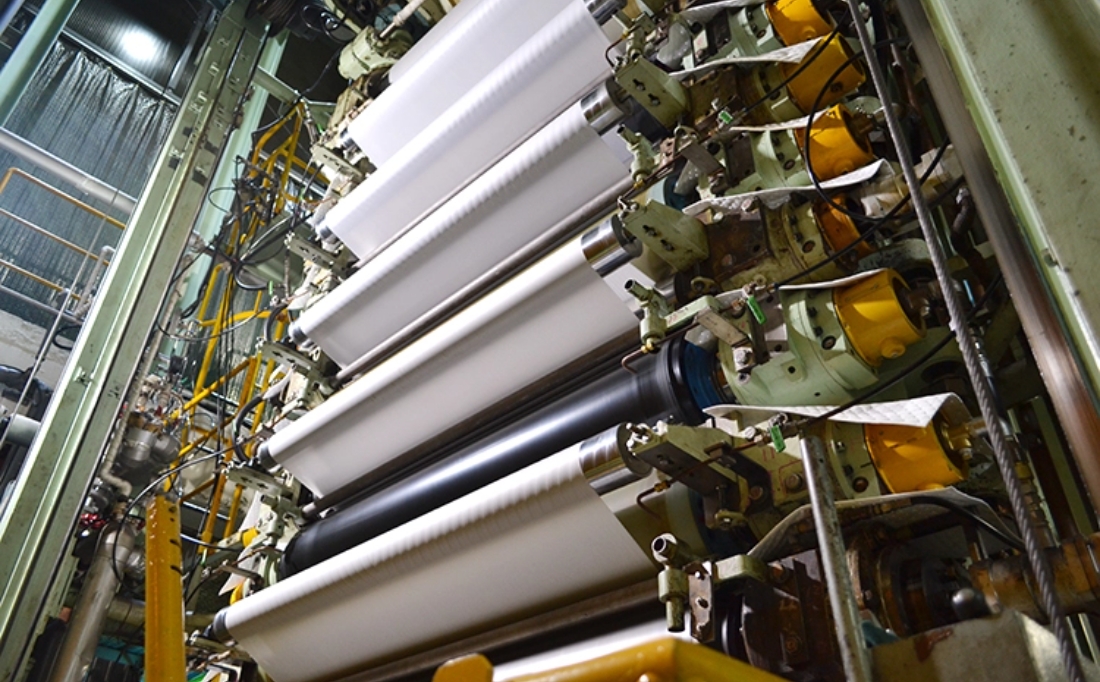

Calendaring

Calendaring smooths the paper surface by passing it between metal rolls under high pressure. This process allows for control over the paper’s finish, from matte to glossy. The thickness of the paper can also be adjusted, and increasing its density can enhance transparency. Additionally, a film-like sheet can be produced by applying high-temperature pressure to base paper containing resin fibers.

The following are key products crafted

with these technologies:

- Printing Paper

- Glassine