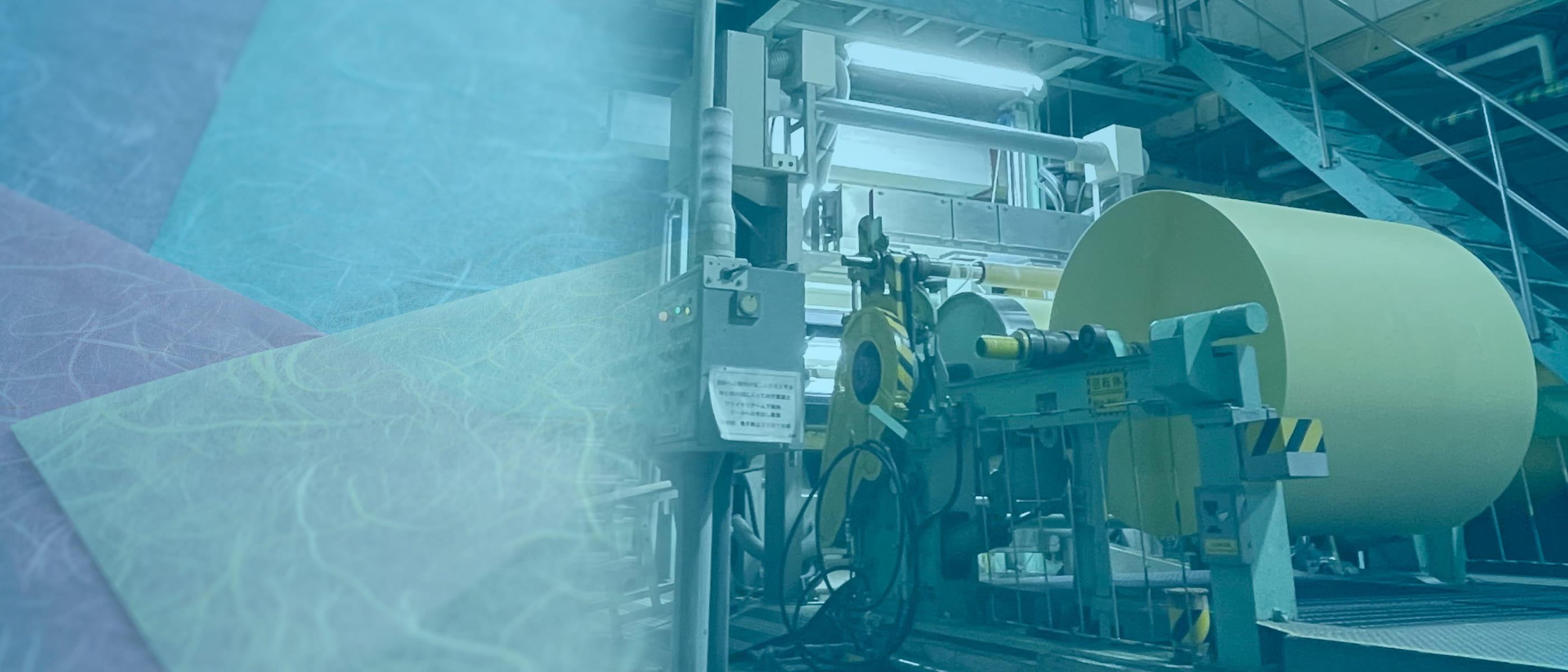

Products

Since our establishment, we have honed our expertise in the fields of thin paper, specialty paper, and functional paper through our unique technologies. Nippon Paper Papylia will continue to deliver exceptional products that meet the diverse needs of our customers.

Product Categories

Functional Paper

The primary functions of paper are display and packaging, but we have evolved and enhanced these to offer a wide range of products with new functionalities.

Specialty Paper

Paper is used in various aspects of daily life and products, enriching people’s lives in numerous ways. While our specialty paper products are used in ways that may often go unnoticed, they contribute to the quality and convenience of everyday living.

Thin Paper

Paper that is thin yet highly opaque or thin but highly transparent—at Nippon Paper Papylia, we are skilled at making both distinct types.

Technical Information

Our expertise lies in creating thin sheets using a variety of raw materials, including wood pulp, cellulose fibers, and synthetic fibers, and we enhance these for strength, flexibility, and heat sealing. We are committed to developing products tailored to your specific needs, so please feel free to contact us with your requirements.

Technical Categories

Thin Paper Making

With years of experience in producing thin paper, we have refined the balance between seemingly contradictory qualities: higher opacity versus greater transparency, and suppleness versus strength. Moreover, we are continually pushing these advancements even further.

Multilayer Papers

with Various

Raw

Materials

Our papermaking, which began with the production of traditional Japanese washi paper using native plants such as mitsumata and kozo, has expanded to use a wide variety of raw materials, from wood pulp to synthetic fibers. By layering these materials together, we are able to give the paper a number of functions and characteristics to meet our customers’ needs.

Creping and

Surface Processing

Creping is a technique that involves creating crepe-like wrinkles on the paper’s surface. As for embossing, we use a carved roll to imprint detailed patterns. The process of calendaring adds to the paper’s luster and smoothness. And our distinctive skills guarantee its enhanced value and functionality.

Impregnation and

Coating

Paper becomes stronger through impregnation, which involves soaking it in a resin liquid to fill the voids within. The paper is then coated to provide specific functionality suited to its intended use.

Sustainability

We are a small paper manufacturer in Japan. However, our raw materials are sourced from around the world, and the production activities at our mills carry significant responsibilities for the local communities and the environment. With this in mind, all our employees think globally while acting locally, dedicated to protecting and improving the environment.

About Us

As a member of the Nippon Paper Group, we oversee the specialty paper division, one of the Group’s core businesses. We were established in April 2008 through the integration of Mishima Paper, Nippon Daishowa Paperboard, and Nippon Paper Industries’ synthetic paper operations. Since our inception, we have refined our expertise in thin paper, specialty paper, and functional products, leveraging the unique technologies developed by each of those companies over many years.